The only thing stronger than our product is our dedication...

Built on a strong foundation of attention to quality and service and dedication to customer satisfaction.

We believe our past to be the best indicator of our future...

The opportunity

In view of the global trend toward rebuilding the world’s infrastructure, the demand for high performance lightweight aggregate is growing.

The rugged durability and outstanding performance record of STALITE Lightweight Slate Aggregate make it the clear choice for meeting or exceeding the design and engineering parameters for buildings, bridges, highways and horticultural applications around the world.

OUR MISSION

- To manufacture and deliver the finest High Performance Lightweight Aggregate across the world

- To provide state-of-the-art technical assistance

- To work tirelessly to assure that our customers are satisfied and have easy access to the highest performing quality lightweight aggregate

“As a quality-driven company, we know the value of listening to our customers, our employees and our community. Their observations and suggestions are factored into who we are and what we produce. We have earned their trust and feel a strong sense of responsibility to keep it.”

THE STALITE STORY

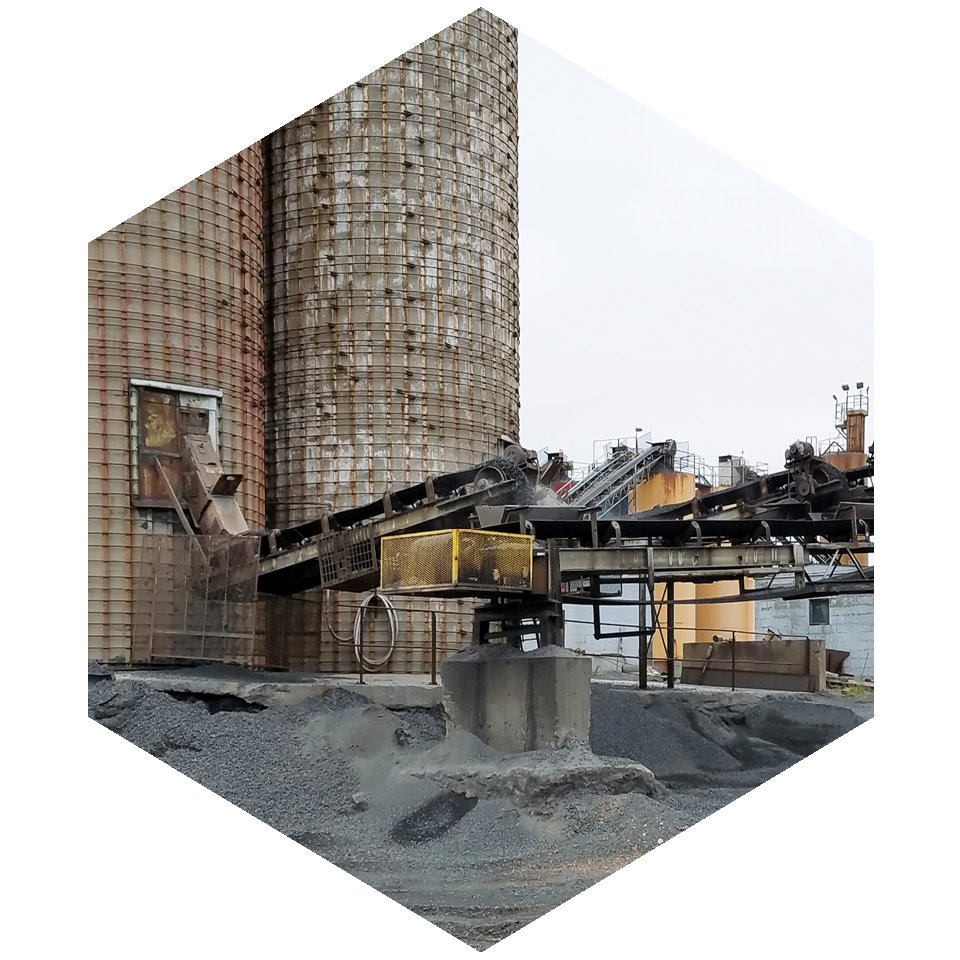

LIGHTWEIGHT AGGREGATE PROCESS AND PRODUCTION

Mining

Staging

Crushing/Stockpiling

Conveying

Manage the Process

Cooking

and...Expanding

Managing & Storing

Collecting

Transporting

Grading-STALITE!!!

Shipping

Quality control

Our goal is to provide the highest quality and most consistent material possible to our customers.

To ensure that we accomplish this goal, we perform the following quality control tests on our raw material and aggregate in our labs at our Gold Hill and Aquadale production facilities each week:

50 raw material gradation tests

85 finished product QC gradation, density and moisture content tests

- 100 production QC gradation and density tests

60 finished product QC relative density tests

200 production QC relative density tests

840 production QC density analysis tests

1,335 Total QC tests performed each week

We also perform a number of other tests on our aggregate to demonstrate compliance with specifications.

Consistency of Material Properties

We have statistically analyzed our relative density and gradation test results since 2003 for each size of coarse aggregate that we produce. The results, demonstrate the success of our commitment to quality and consistency.